Planetary Extruder for PVC

The planetary extruder is the most important link in the PVC production line. Its stability and durability are the foundation of the entire production line.

Self-cleaning properties

The 45-degree helical angle of the planetary extruder’s intermeshing multi-screw structure endows the planetary mixing section with a high degree of self-cleaning capability.

Friendly to production requirements

The simple and efficient feeding and plasticizing capabilities make it easy to adjust formula ratios, while also facilitating fine-tuning of production parameters.

Online recycling of edge materials

The efficient intermeshing capability of the multi-screw allows the edge materials produced to be directly fed into the hopper after being crushed by a small crusher, without the need to consider the handling and placement of edge materials, thus achieving simple and efficient cost savings.

Flexible production adjustment

Unlike single and twin-screw extruders, the shear heat generated by the intermeshing multi-screw structure of the planetary extruder allows for normal production even under low-speed feeding conditions, thereby better adjusting the production line.

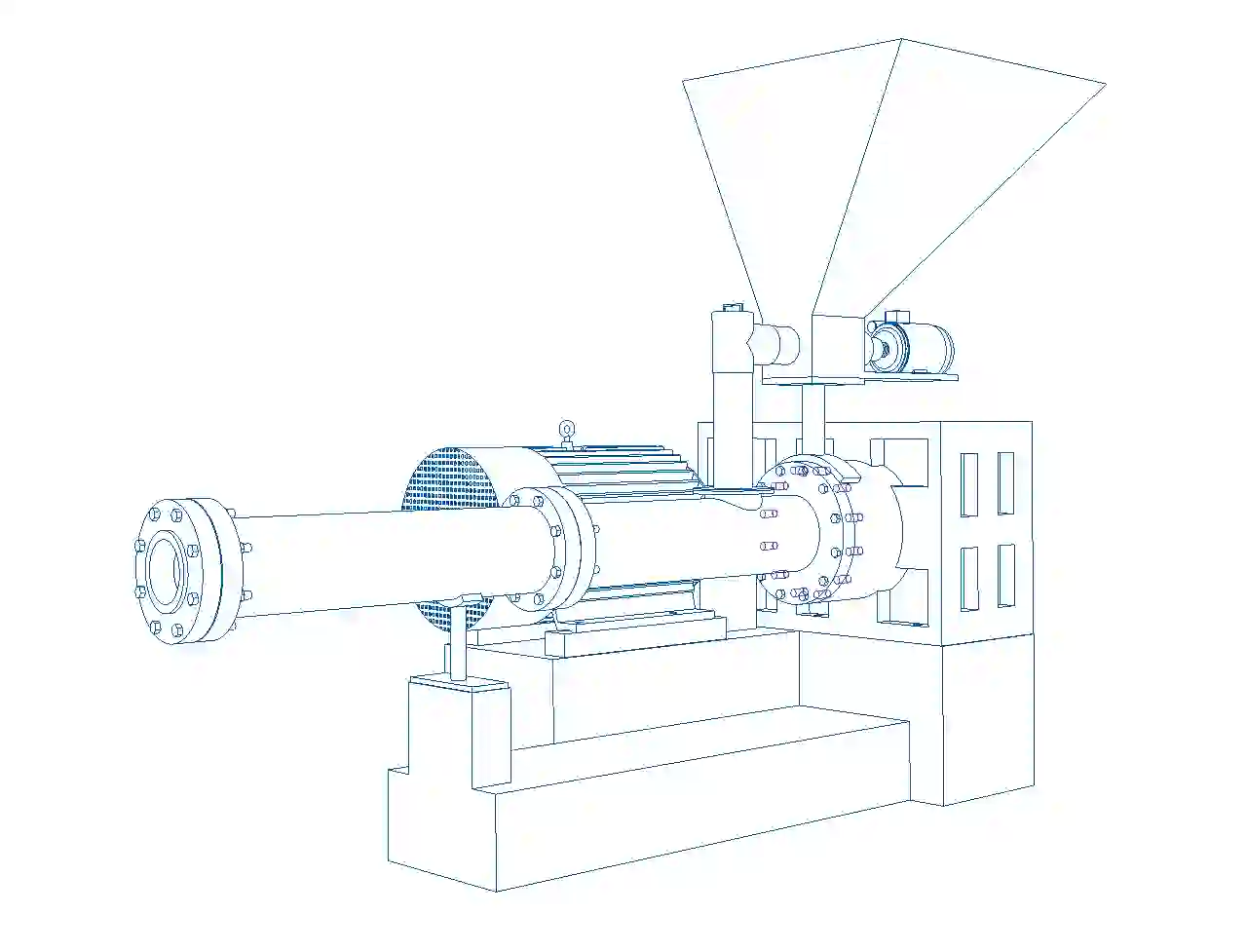

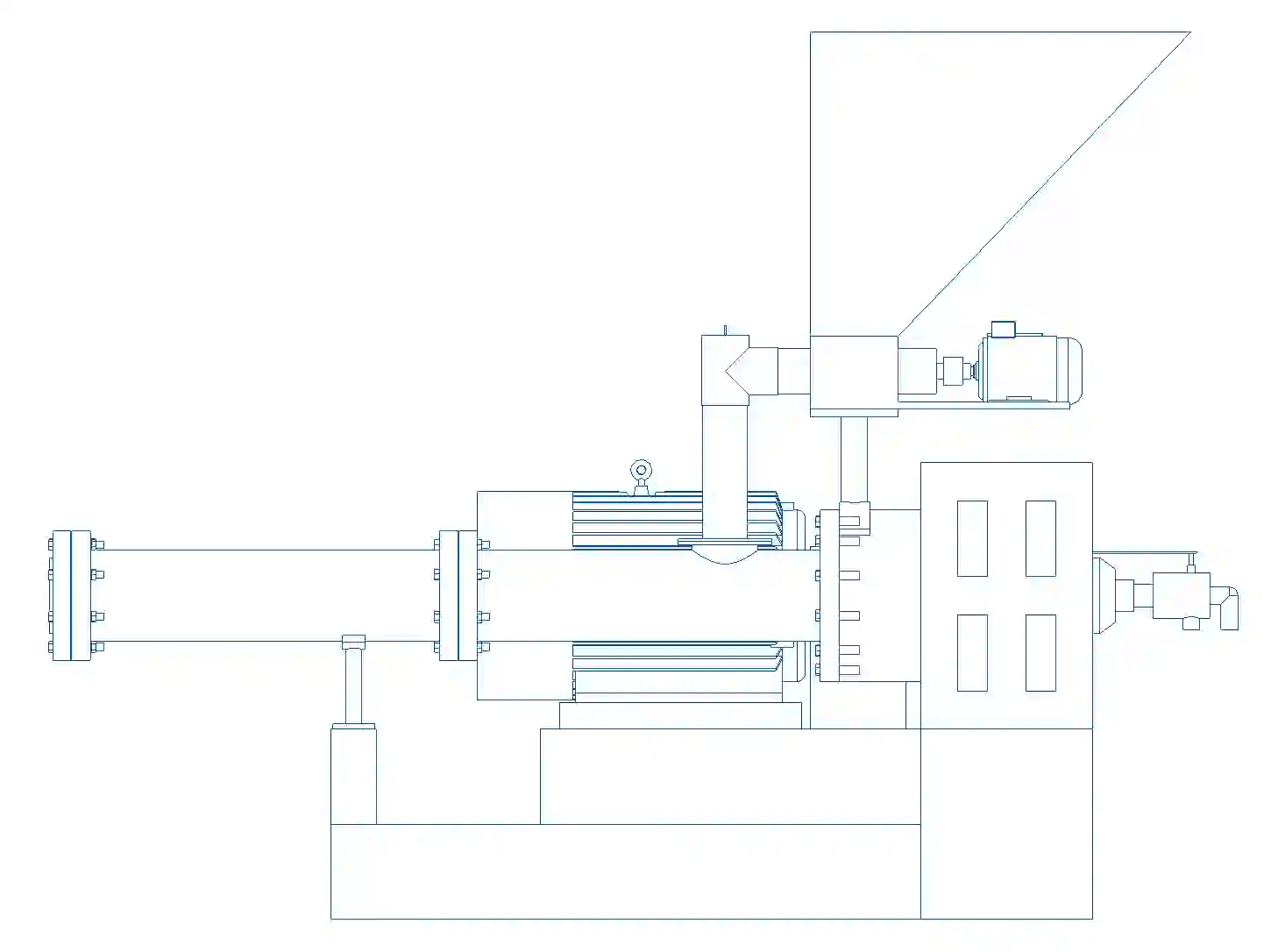

Planetary Extruder for PVC

The entire equipment offers a high degree of customization to meet the diverse production needs of different clients, including but not limited to the selection of main motor types and power, the style of the feeder, and the optional configuration of metal separators.

Brief specifications and technical parameters

| Model | Motor power | Oil heater power | extrusion volume of PVC sheet material(h) |

|---|---|---|---|

| 125 | 55KW | 9kw*2 | 350kg |

| 150(s) | 75kw | 12kw*2 | 500kg / 600kg |

| 170(s) | 110kw | 12kw+18kw | 700kg / 800kg |

| 190(s) | 160kw | 12kw+18kw | 1100kg / 1200kg |

If necessary, we have additional specifications of equipment available for selection.

The parameters above are for reference only, and any subsequent changes may not be updated promptly.

Sample Image (does not represent all specifications)